*Plus VAT. Course can be viewed and edited for one year after activation. Price is per participant. Access data are personalized and may not be passed on.

Course format: #Spotlight

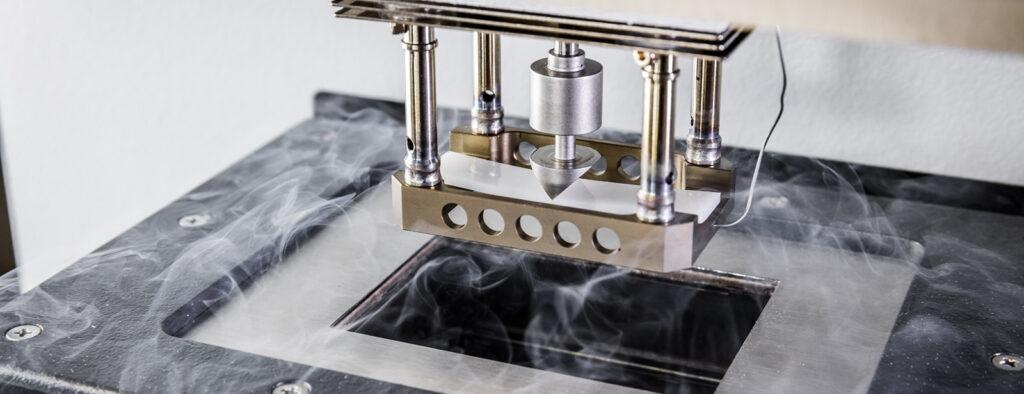

#Spotlight: Additive Manufacturing

The Spotlight will feature the possibility of material modification of 3D printing materials. Thermally conductive materials are on everyone’s lips. Especially for the electronics industry, where heat has to be dissipated from the electronics, thermally conductive plastics play an important role. However, such material modifications can also be imagined with other functions. Keywords here are antibacterial, antiviral or even EMC shielding. In combination with additive manufacturing, completely new possibilities arise for this fast-growing industry.

Objectives: Modification of materials for additive manufacturing in order to be able to realize properties of injection molded components in the prototype phase / development close to series production by means of 3D printing.

Target group: Design engineers, product and assembly developers, project managers from all areas of additive manufacturing / plastics technology.