What is the Plastics School?

The Plastics School is the digital learning platform for the plastics sector. With it, the Kunststoff-Institut Lüdenscheid offers new ways of digital learning and thus actively takes up the demands of the economy for agile digital solutions. Gradually, many of the institute’s face-to-face seminars will be bookable here. In addition, there is exclusive online content in the Plastics School.

The e-learning seminars are more compact in terms of content than the face-to-face seminars. The learner decides for himself whether he wants to work through the entire course at once, or whether he wants to learn with smaller breaks. After completing the course, the participant receives a certificate for what he or she has learned.

Your benefits

You and your employees will benefit in a variety of ways from the Plastics School courses:

- Time flexible learning

- Compact Units

- Practice-oriented

- Always State of the Art

- Continuously new content

- Exclusive collaborations

- Interactive tests

- Lifelong learning

“Introduction to Injection Molding” seminar

Our Introduction to Injection Molding Technology provides employees from non-technical backgrounds with a detailed but easy-to-understand look at injection molding technology. Get free access to an abridged trial version of the course consisting of the introduction and an instructional video.

Get courses

- All Courses

- e-Learning Courses

- „On-Demand“ Online Seminar

- #Spotlight

- Trainee Courses

- ENGEL e-Learning Courses

- External Courses

Introduction to Injection Molding

Introduction to Injection Molding Technology provides employees from non-technical fields with a detailed but easy-to-understand insight into injection molding technology. The topics covered range from materials science and machine and mold technology to the environment and processing.

Basics of PVD coating

This online seminar provides a fundamental understanding of the different PVD processes and addresses important aspects of PVD coating of plastics.

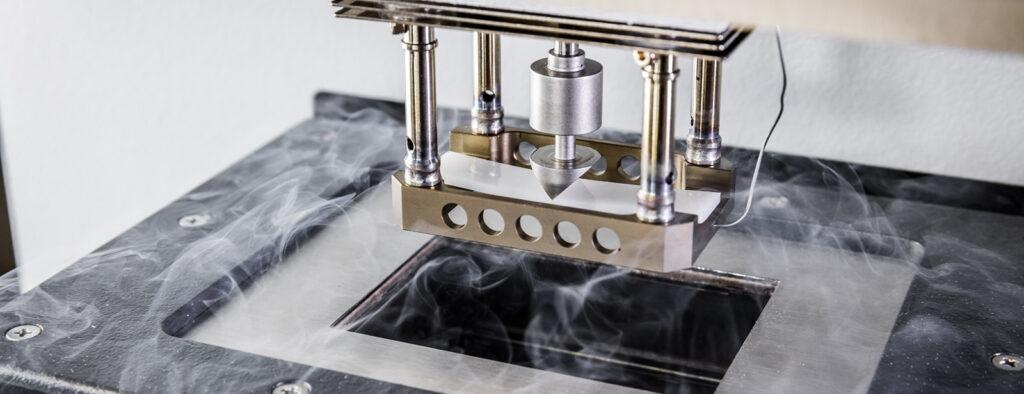

#Spotlight: Tool coating

Tool surfaces in injection molding must withstand high temperature and pressure loads and be resistant to wear. Targeted coating of the often very expensive tools can produce higher-quality injection molded components and increase the service life of the tools.

#Spotlight: Additive Manufacturing

Thermally conductive materials play an important role not only in the electronics industry: they also have antiviral and antibacterial properties and can be used for EMC shielding. Combined with additive manufacturing, this opens up entirely new possibilities for this fast-growing industry.

Recyclate or not, that is the question

The use of regrind, regranulate and co. is accompanied by concerns about material quality for some processors. This seminar provides an overview of current analytical methods to address issues of purity, material degradation, and granule composition and to assist in the evaluation of recyclates.

#Spotlight: Good or bad parts

Plastic parts are exposed to a wide variety of environmental conditions in use, which can cause the parts to break, crack or have other defects. Selected tests can assist in classifying whether the component is a “good” or a “bad” part.

Materials testing to automotive standards

All plastics and various other materials emit emissions. A wide variety of methods are required to identify and classify these. Before a material or component reaches the end customer, it is tested to determine whether it is potentially toxic, can form a coating or simply smells unpleasant.

Exam preparation: Process mechanic for plastics & rubber technology (specialization molded parts)

Trainees as process mechanics for plastics and rubber technology (specialization molded parts) are given an insight into the procedure of a practical AP2 final examination.

#Spotlight: Lubricant management on injection molding machines

The ideal use of existing resources is certainly the aspiration of many. The reasons for this, in addition to economic cost efficiency, are nowadays above all sustainability. In order to achieve both, the lubricant plays a decisive role in the production of plastic injection molded parts in industry.

#Spotlight: What does New Work have to do with innovation?

GENERATION DESIGN GmbH from Wuppertal got to the bottom of this question in our joint #Spotlight. In this live recording, successful, creative methods and processes for strategic work are presented and tools are shown to make the development of an “innovation roadmap” clearer and easier.

#Spotlight: Project funding programs go-inno and go-digital

The digitization of companies is also supported! The company lllusionFACTORY KG is an accredited consultant in the funding program go-digital and will illustrate to you, among other things, what funding advice can look like and what is important for successful digitization projects.

Basic knowledge for operating ENGEL injection moulding machines

The participant learns to master the operation and setting of the clamping and injection unit of ENGEL injection moulding machines. He will be able to carry out setup procedures and production settings independently and effectively, taking into account the ENGEL-specific machine control system.

Operating ENGEL injection moulding machines for advanced users

Operating ENGEL injection moulding machines for advanced users. Improve participants’ ability to operate ENGEL injection moulding machines. After the seminar, the participants will be able to set up more complex sequences quickly and effectively, and perform production and quality optimisation.

Basic knowledge for operating ENGEL viper linear robots

Basic skills for operating ENGEL viper linear robots. After the seminar, the participants will be familiar with the mechanical layout and the controls, and capable of setting up and using standard programmes.

Data Protection Basic Training

In the Data Privacy Basic Training, your employees will learn the most important basics of data privacy in less than 30 minutes – in a practical, informative and legally compliant manner. The data protection e-learning requires no knowledge of the basics and is suitable for all employees.

Basic instruction in occupational health and safety

In our basic occupational safety training, your employees will learn the most important basics of occupational safety in 60 minutes – in a practical, informative and legally compliant manner. Your employees receive a certificate for successful participation in a course.

E-Business-Leader

Digital know-how is also increasingly in demand in the plastics industry. A defined course objective in the “E-Business-Leader” is the development of currently professionally relevant competencies specifically for business management in the digital age.

E-Business-Manager

Digital know-how is also increasingly in demand in the plastics industry. Together with the University of Duisburg Essen and the Codingschule, the Kunststoff-Institut Lüdenscheid is offering a unique digital training for managers in the plastics industry in 2021.

#Spotlight: Cyber Security: The TOP mistakes and how to avoid them

Every day, a large number of companies in Germany fall victim to cyber attacks. With serious consequences, such as extortion money, production standstill as well as costs for data protection violations. This course will teach about the threat situation, possibilities of prevention and the possibilities of protection via cyber insurance.

#Spotlight: Challenges for B2B Operations - How a Virus Affects Entrepreneurial Motivation

Frank Stampa is the Head of Sales at FoxBase GmbH. In this #Spotlight, he discusses the changes to traditional sales in the course of digitization in a relaxed exchange. What are the new demands on suppliers from the customer side? What role did the Covid pandemic also play in this?

#Spotlight: Introducing Haitian International Germany

Haitian International Germany support all plastics processing industries with highly efficient Haitian and Zhafir machines, complemented by comprehensive support and services at a high level. In this #Spotlight you will get an exciting insight into the company's philosophy.

Trainee Online School

Andreas Plöhn, master process mechanic for plastics and rubber and for almost 30 years at the Kunststoff-Institut Lüdenscheid, provides participants with a holistic and practical view of the entire injection molding process, starting with the basics of plastics, through the design of an injection mold, to molding defects.

Introduction to Injection Molding

Introduction to Injection Molding Technology provides employees from non-technical fields with a detailed but easy-to-understand insight into injection molding technology. The topics covered range from materials science and machine and mold technology to the environment and processing.

Basics of PVD coating

This online seminar provides a fundamental understanding of the different PVD processes and addresses important aspects of PVD coating of plastics.

#Spotlight: Tool coating

Tool surfaces in injection molding must withstand high temperature and pressure loads and be resistant to wear. Targeted coating of the often very expensive tools can produce higher-quality injection molded components and increase the service life of the tools.

#Spotlight: Additive Manufacturing

Thermally conductive materials play an important role not only in the electronics industry: they also have antiviral and antibacterial properties and can be used for EMC shielding. Combined with additive manufacturing, this opens up entirely new possibilities for this fast-growing industry.

Recyclate or not, that is the question

The use of regrind, regranulate and co. is accompanied by concerns about material quality for some processors. This seminar provides an overview of current analytical methods to address issues of purity, material degradation, and granule composition and to assist in the evaluation of recyclates.

#Spotlight: Good or bad parts

Plastic parts are exposed to a wide variety of environmental conditions in use, which can cause the parts to break, crack or have other defects. Selected tests can assist in classifying whether the component is a “good” or a “bad” part.

Materials testing to automotive standards

All plastics and various other materials emit emissions. A wide variety of methods are required to identify and classify these. Before a material or component reaches the end customer, it is tested to determine whether it is potentially toxic, can form a coating or simply smells unpleasant.

Exam preparation: Process mechanic for plastics & rubber technology (specialization molded parts)

Trainees as process mechanics for plastics and rubber technology (specialization molded parts) are given an insight into the procedure of a practical AP2 final examination.

#Spotlight: Lubricant management on injection molding machines

The ideal use of existing resources is certainly the aspiration of many. The reasons for this, in addition to economic cost efficiency, are nowadays above all sustainability. In order to achieve both, the lubricant plays a decisive role in the production of plastic injection molded parts in industry.

#Spotlight: What does New Work have to do with innovation?

GENERATION DESIGN GmbH from Wuppertal got to the bottom of this question in our joint #Spotlight. In this live recording, successful, creative methods and processes for strategic work are presented and tools are shown to make the development of an “innovation roadmap” clearer and easier.

#Spotlight: Project funding programs go-inno and go-digital

The digitization of companies is also supported! The company lllusionFACTORY KG is an accredited consultant in the funding program go-digital and will illustrate to you, among other things, what funding advice can look like and what is important for successful digitization projects.

Basic knowledge for operating ENGEL injection moulding machines

The participant learns to master the operation and setting of the clamping and injection unit of ENGEL injection moulding machines. He will be able to carry out setup procedures and production settings independently and effectively, taking into account the ENGEL-specific machine control system.

Operating ENGEL injection moulding machines for advanced users

Operating ENGEL injection moulding machines for advanced users. Improve participants’ ability to operate ENGEL injection moulding machines. After the seminar, the participants will be able to set up more complex sequences quickly and effectively, and perform production and quality optimisation.

Basic knowledge for operating ENGEL viper linear robots

Basic skills for operating ENGEL viper linear robots. After the seminar, the participants will be familiar with the mechanical layout and the controls, and capable of setting up and using standard programmes.

Data Protection Basic Training

In the Data Privacy Basic Training, your employees will learn the most important basics of data privacy in less than 30 minutes – in a practical, informative and legally compliant manner. The data protection e-learning requires no knowledge of the basics and is suitable for all employees.

Basic instruction in occupational health and safety

In our basic occupational safety training, your employees will learn the most important basics of occupational safety in 60 minutes – in a practical, informative and legally compliant manner. Your employees receive a certificate for successful participation in a course.

E-Business-Leader

Digital know-how is also increasingly in demand in the plastics industry. A defined course objective in the “E-Business-Leader” is the development of currently professionally relevant competencies specifically for business management in the digital age.

E-Business-Manager

Digital know-how is also increasingly in demand in the plastics industry. Together with the University of Duisburg Essen and the Codingschule, the Kunststoff-Institut Lüdenscheid is offering a unique digital training for managers in the plastics industry in 2021.

#Spotlight: Cyber Security: The TOP mistakes and how to avoid them

Every day, a large number of companies in Germany fall victim to cyber attacks. With serious consequences, such as extortion money, production standstill as well as costs for data protection violations. This course will teach about the threat situation, possibilities of prevention and the possibilities of protection via cyber insurance.

#Spotlight: Challenges for B2B Operations - How a Virus Affects Entrepreneurial Motivation

Frank Stampa is the Head of Sales at FoxBase GmbH. In this #Spotlight, he discusses the changes to traditional sales in the course of digitization in a relaxed exchange. What are the new demands on suppliers from the customer side? What role did the Covid pandemic also play in this?

#Spotlight: Introducing Haitian International Germany

Haitian International Germany support all plastics processing industries with highly efficient Haitian and Zhafir machines, complemented by comprehensive support and services at a high level. In this #Spotlight you will get an exciting insight into the company's philosophy.

Trainee Online School

Andreas Plöhn, master process mechanic for plastics and rubber and for almost 30 years at the Kunststoff-Institut Lüdenscheid, provides participants with a holistic and practical view of the entire injection molding process, starting with the basics of plastics, through the design of an injection mold, to molding defects.

Introduction to Injection Molding

Introduction to Injection Molding Technology provides employees from non-technical fields with a detailed but easy-to-understand insight into injection molding technology. The topics covered range from materials science and machine and mold technology to the environment and processing.

Introduction to Injection Molding

Introduction to Injection Molding Technology provides employees from non-technical fields with a detailed but easy-to-understand insight into injection molding technology. The topics covered range from materials science and machine and mold technology to the environment and processing.

Basics of PVD coating

This online seminar provides a fundamental understanding of the different PVD processes and addresses important aspects of PVD coating of plastics.

Recyclate or not, that is the question

The use of regrind, regranulate and co. is accompanied by concerns about material quality for some processors. This seminar provides an overview of current analytical methods to address issues of purity, material degradation, and granule composition and to assist in the evaluation of recyclates.

Materials testing to automotive standards

All plastics and various other materials emit emissions. A wide variety of methods are required to identify and classify these. Before a material or component reaches the end customer, it is tested to determine whether it is potentially toxic, can form a coating or simply smells unpleasant.

Basics of PVD coating

This online seminar provides a fundamental understanding of the different PVD processes and addresses important aspects of PVD coating of plastics.

Recyclate or not, that is the question

The use of regrind, regranulate and co. is accompanied by concerns about material quality for some processors. This seminar provides an overview of current analytical methods to address issues of purity, material degradation, and granule composition and to assist in the evaluation of recyclates.

Materials testing to automotive standards

All plastics and various other materials emit emissions. A wide variety of methods are required to identify and classify these. Before a material or component reaches the end customer, it is tested to determine whether it is potentially toxic, can form a coating or simply smells unpleasant.

#Spotlight: Tool coating

Tool surfaces in injection molding must withstand high temperature and pressure loads and be resistant to wear. Targeted coating of the often very expensive tools can produce higher-quality injection molded components and increase the service life of the tools.

#Spotlight: Additive Manufacturing

Thermally conductive materials play an important role not only in the electronics industry: they also have antiviral and antibacterial properties and can be used for EMC shielding. Combined with additive manufacturing, this opens up entirely new possibilities for this fast-growing industry.

#Spotlight: Good or bad parts

Plastic parts are exposed to a wide variety of environmental conditions in use, which can cause the parts to break, crack or have other defects. Selected tests can assist in classifying whether the component is a “good” or a “bad” part.

#Spotlight: Lubricant management on injection molding machines

The ideal use of existing resources is certainly the aspiration of many. The reasons for this, in addition to economic cost efficiency, are nowadays above all sustainability. In order to achieve both, the lubricant plays a decisive role in the production of plastic injection molded parts in industry.

#Spotlight: What does New Work have to do with innovation?

GENERATION DESIGN GmbH from Wuppertal got to the bottom of this question in our joint #Spotlight. In this live recording, successful, creative methods and processes for strategic work are presented and tools are shown to make the development of an “innovation roadmap” clearer and easier.

#Spotlight: Project funding programs go-inno and go-digital

The digitization of companies is also supported! The company lllusionFACTORY KG is an accredited consultant in the funding program go-digital and will illustrate to you, among other things, what funding advice can look like and what is important for successful digitization projects.

#Spotlight: Cyber Security: The TOP mistakes and how to avoid them

Every day, a large number of companies in Germany fall victim to cyber attacks. With serious consequences, such as extortion money, production standstill as well as costs for data protection violations. This course will teach about the threat situation, possibilities of prevention and the possibilities of protection via cyber insurance.

#Spotlight: Challenges for B2B Operations - How a Virus Affects Entrepreneurial Motivation

Frank Stampa is the Head of Sales at FoxBase GmbH. In this #Spotlight, he discusses the changes to traditional sales in the course of digitization in a relaxed exchange. What are the new demands on suppliers from the customer side? What role did the Covid pandemic also play in this?

#Spotlight: Introducing Haitian International Germany

Haitian International Germany support all plastics processing industries with highly efficient Haitian and Zhafir machines, complemented by comprehensive support and services at a high level. In this #Spotlight you will get an exciting insight into the company's philosophy.

#Spotlight: Tool coating

Tool surfaces in injection molding must withstand high temperature and pressure loads and be resistant to wear. Targeted coating of the often very expensive tools can produce higher-quality injection molded components and increase the service life of the tools.

#Spotlight: Additive Manufacturing

Thermally conductive materials play an important role not only in the electronics industry: they also have antiviral and antibacterial properties and can be used for EMC shielding. Combined with additive manufacturing, this opens up entirely new possibilities for this fast-growing industry.

#Spotlight: Good or bad parts

Plastic parts are exposed to a wide variety of environmental conditions in use, which can cause the parts to break, crack or have other defects. Selected tests can assist in classifying whether the component is a “good” or a “bad” part.

#Spotlight: Lubricant management on injection molding machines

The ideal use of existing resources is certainly the aspiration of many. The reasons for this, in addition to economic cost efficiency, are nowadays above all sustainability. In order to achieve both, the lubricant plays a decisive role in the production of plastic injection molded parts in industry.

#Spotlight: What does New Work have to do with innovation?

GENERATION DESIGN GmbH from Wuppertal got to the bottom of this question in our joint #Spotlight. In this live recording, successful, creative methods and processes for strategic work are presented and tools are shown to make the development of an “innovation roadmap” clearer and easier.

#Spotlight: Project funding programs go-inno and go-digital

The digitization of companies is also supported! The company lllusionFACTORY KG is an accredited consultant in the funding program go-digital and will illustrate to you, among other things, what funding advice can look like and what is important for successful digitization projects.

#Spotlight: Cyber Security: The TOP mistakes and how to avoid them

Every day, a large number of companies in Germany fall victim to cyber attacks. With serious consequences, such as extortion money, production standstill as well as costs for data protection violations. This course will teach about the threat situation, possibilities of prevention and the possibilities of protection via cyber insurance.

#Spotlight: Challenges for B2B Operations - How a Virus Affects Entrepreneurial Motivation

Frank Stampa is the Head of Sales at FoxBase GmbH. In this #Spotlight, he discusses the changes to traditional sales in the course of digitization in a relaxed exchange. What are the new demands on suppliers from the customer side? What role did the Covid pandemic also play in this?

#Spotlight: Introducing Haitian International Germany

Haitian International Germany support all plastics processing industries with highly efficient Haitian and Zhafir machines, complemented by comprehensive support and services at a high level. In this #Spotlight you will get an exciting insight into the company's philosophy.

Exam preparation: Process mechanic for plastics & rubber technology (specialization molded parts)

Trainees as process mechanics for plastics and rubber technology (specialization molded parts) are given an insight into the procedure of a practical AP2 final examination.

Trainee Online School

Andreas Plöhn, master process mechanic for plastics and rubber and for almost 30 years at the Kunststoff-Institut Lüdenscheid, provides participants with a holistic and practical view of the entire injection molding process, starting with the basics of plastics, through the design of an injection mold, to molding defects.

Exam preparation: Process mechanic for plastics & rubber technology (specialization molded parts)

Trainees as process mechanics for plastics and rubber technology (specialization molded parts) are given an insight into the procedure of a practical AP2 final examination.

Trainee Online School

Andreas Plöhn, master process mechanic for plastics and rubber and for almost 30 years at the Kunststoff-Institut Lüdenscheid, provides participants with a holistic and practical view of the entire injection molding process, starting with the basics of plastics, through the design of an injection mold, to molding defects.

Basic knowledge for operating ENGEL injection moulding machines

The participant learns to master the operation and setting of the clamping and injection unit of ENGEL injection moulding machines. He will be able to carry out setup procedures and production settings independently and effectively, taking into account the ENGEL-specific machine control system.

Operating ENGEL injection moulding machines for advanced users

Operating ENGEL injection moulding machines for advanced users. Improve participants’ ability to operate ENGEL injection moulding machines. After the seminar, the participants will be able to set up more complex sequences quickly and effectively, and perform production and quality optimisation.

Basic knowledge for operating ENGEL injection moulding machines

The participant learns to master the operation and setting of the clamping and injection unit of ENGEL injection moulding machines. He will be able to carry out setup procedures and production settings independently and effectively, taking into account the ENGEL-specific machine control system.

Operating ENGEL injection moulding machines for advanced users

Operating ENGEL injection moulding machines for advanced users. Improve participants’ ability to operate ENGEL injection moulding machines. After the seminar, the participants will be able to set up more complex sequences quickly and effectively, and perform production and quality optimisation.

Basic knowledge for operating ENGEL viper linear robots

Basic skills for operating ENGEL viper linear robots. After the seminar, the participants will be familiar with the mechanical layout and the controls, and capable of setting up and using standard programmes.

Data Protection Basic Training

In the Data Privacy Basic Training, your employees will learn the most important basics of data privacy in less than 30 minutes – in a practical, informative and legally compliant manner. The data protection e-learning requires no knowledge of the basics and is suitable for all employees.

Basic instruction in occupational health and safety

In our basic occupational safety training, your employees will learn the most important basics of occupational safety in 60 minutes – in a practical, informative and legally compliant manner. Your employees receive a certificate for successful participation in a course.

E-Business-Leader

Digital know-how is also increasingly in demand in the plastics industry. A defined course objective in the “E-Business-Leader” is the development of currently professionally relevant competencies specifically for business management in the digital age.

Data Protection Basic Training

In the Data Privacy Basic Training, your employees will learn the most important basics of data privacy in less than 30 minutes – in a practical, informative and legally compliant manner. The data protection e-learning requires no knowledge of the basics and is suitable for all employees.

Basic instruction in occupational health and safety

In our basic occupational safety training, your employees will learn the most important basics of occupational safety in 60 minutes – in a practical, informative and legally compliant manner. Your employees receive a certificate for successful participation in a course.

E-Business-Leader

Digital know-how is also increasingly in demand in the plastics industry. A defined course objective in the “E-Business-Leader” is the development of currently professionally relevant competencies specifically for business management in the digital age.

E-Business-Manager

Digital know-how is also increasingly in demand in the plastics industry. Together with the University of Duisburg Essen and the Codingschule, the Kunststoff-Institut Lüdenscheid is offering a unique digital training for managers in the plastics industry in 2021.